Subzero Industrial Camera ATEX Rated – Safe in Cold, Hazardous Areas!

I used a subzero industrial camera with ATEX rating in very cold and dangerous places. It worked great and gave clear pictures even in freezing weather. This camera is perfect if you need something safe and strong for cold, risky areas.

Subzero industrial cameras with ATEX rating are made to work safely in cold and dangerous places. They have heaters and strong covers to keep working well in freezing temperatures. These cameras are very important for industries like oil, gas, and chemicals where safety is a must.

Stay tuned with us! We will talk more about subzero industrial cameras with ATEX rating and how they can help you in cold and risky environments.

What is a Subzero Industrial Camera? – Explore Features!

A subzero industrial camera is a special type of camera made to work in extremely cold environments. These cameras are built with rugged materials that can handle freezing temperatures, snow, ice, and harsh conditions without failing.

They are often used in dangerous or remote areas where normal cameras would stop working due to the cold. These cameras are also designed to resist water, dust, and impacts, making them perfect for industrial use.

Purpose of Subzero Industrial Cameras

The main purpose of a subzero industrial camera is to provide clear and reliable video or image monitoring in places where temperatures drop below zero.

They help workers and safety teams:

- Monitor equipment and operations.

- Improve safety in dangerous areas.

- Record footage for inspection or security.

- Operate without needing repairs in extreme cold.

These cameras are especially helpful when paired with ATEX certification, which allows them to work in places with explosive gases or dust.

Key Industries That Use Them

Subzero ATEX-rated cameras are used in many industries, especially where cold and explosive risks are common. Some of the key industries include:

- Oil and Gas: for pipelines, rigs, and refineries in Arctic or offshore areas.

- Mining: underground or surface mines in freezing regions.

- Chemical Plants: where both cold and explosive materials are present.

- Cold Storage and Logistics: warehouses or transport systems storing frozen goods.

- Military and Defense: used in polar bases or cold-weather missions.

- Energy and Utilities: wind farms or power stations in subzero areas.

Temperature Ranges Typically Supported

Most subzero industrial cameras are rated to operate in temperatures as low as -40°C to -50°C (-40°F to -58°F).

High-end models can work in even colder climates, especially when used in places like the Arctic or at high altitudes.

These cameras often include built-in heaters or special enclosures to prevent freezing and keep the lens clear for smooth operation.

Understanding ATEX Certification – Explore Features!

What Does ATEX Stand For?

ATEX stands for “Atmosphères Explosibles“—a European Union directive that makes sure electrical and mechanical equipment is safe to use in explosive environments.

The ATEX certification proves that a device, like an industrial camera, is built to avoid causing explosions, even when used around flammable gases, dust, or vapors.

There are two main directives under ATEX:

- ATEX 114 (Directive 2014/34/EU): for equipment and protective systems.

- ATEX 153 (Directive 1999/92/EC): for workplace safety.

ATEX Zones Explained (Zone 0, 1, 2)

ATEX divides hazardous areas into zones based on how likely an explosive atmosphere is present. This helps match the right equipment to the level of risk.

Here’s a quick breakdown:

- Zone 0: Explosive gas is present all the time or for long periods.

(Highest risk – needs the safest equipment.) - Zone 1: Explosive gas is likely to occur sometimes during normal operations.

- Zone 2: Explosive gas is unlikely during normal use, and if it happens, it’s only for a short time.

(Lower risk, but still needs approved equipment.)

For dust-based environments, there are also Zones 20, 21, and 22, which follow similar rules.

Why ATEX Compliance is Crucial

Using non-ATEX equipment in hazardous environments can be very dangerous. Even a small spark or heat from a regular camera can cause an explosion if flammable gas or dust is nearby.

That’s why ATEX-certified cameras are designed to:

- Prevent sparks or heat from escaping.

- Work safely in gas, vapor, or dust environments.

- Stay sealed and protected even in tough conditions.

ATEX compliance is legally required in many industries like oil & gas, chemical plants, and refineries across Europe and other regions that follow similar safety rules.

By using an ATEX-rated subzero industrial camera, companies ensure both safety and legal compliance while also avoiding downtime, fines, or accidents.

Where Are These Cameras Used? – Top Use Cases!

Subzero industrial ATEX-rated cameras are used in places where both extreme cold and explosive hazards are common. These environments are often remote, harsh, and dangerous—so reliable and safe monitoring is a must.

Below are the most common use cases:

1. Oil Rigs and Offshore Platforms

In the oil and gas industry, these cameras are installed on drilling rigs, offshore platforms, and pipeline stations.

They help operators monitor equipment and detect leaks or fires, even in freezing temperatures and Zone 1 or Zone 2 ATEX-rated areas.

2. Chemical and Petrochemical Plants

These plants deal with flammable chemicals and gases, making ATEX certification essential.

Subzero cameras are used in outdoor tanks, pipelines, and cold storage zones to ensure safety and prevent explosions during extreme weather.

3. Mining Operations

In cold-region mines or high-altitude sites, temperatures often drop below zero.

ATEX-rated cameras help monitor blast zones, conveyor belts, and machinery, where dust and gas explosions are a risk.

4. Cold Storage Facilities

In logistics and food industries, subzero cameras are used in freezers and refrigerated warehouses to track storage conditions, prevent product loss, and boost safety—especially where coolants or gases may be flammable.

5. Power Plants and Utilities

These cameras are used in nuclear, hydro, and gas power plants—especially in areas exposed to the elements or with hazardous materials.

They provide 24/7 monitoring during cold winters or arctic conditions, helping teams detect early signs of danger.

6. Military and Defense Zones

Used in remote border stations, polar outposts, and weapon storage areas, these cameras offer reliable video surveillance in harsh and explosive-risk environments.

7. Aviation and Aerospace Facilities

Fuel storage zones, hangars, and outdoor tarmacs in extreme weather airports also benefit from subzero ATEX-rated cameras, keeping operations secure in both cold and combustible conditions.

Best Subzero Industrial ATEX-Rated Cameras – 2025 Picks!

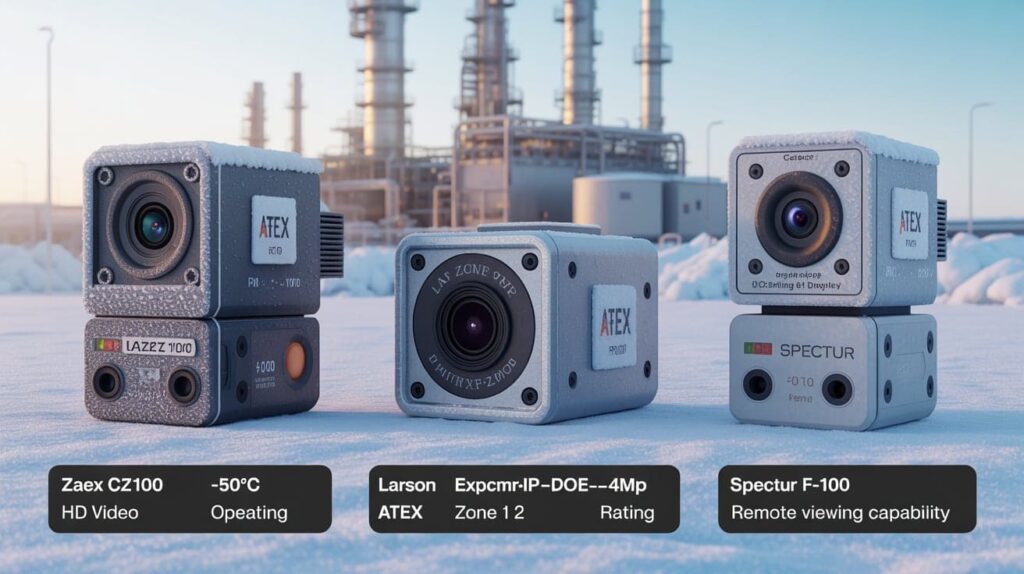

In 2025, top models like the ZAEX CZ100, Larson EXPCMR-IP-POE-4MP, and Spectur F-100 are great choices. These cameras work in extreme cold (as low as -50°C) and are ATEX-rated for use in explosive areas. They also come with HD video, tough housings, and built-in heaters.

When picking a camera, check if it’s rated for Zone 1 or Zone 2. Also, choose one with strong materials, weatherproof build, and remote viewing. These features help keep your site safe in cold and risky areas.

Installation Tips for Subzero ATEX Cameras – Follow Guidelines!

- Check the ATEX Zone: Before installing the camera, always check if the location falls under Zone 0, 1, or 2. Using the wrong camera for the zone can lead to safety issues or non-compliance with regulations.

- Use Proper Mounting Gear: Make sure to use strong, ATEX-approved mounting brackets built for cold environments. Regular mounts may crack or come loose in freezing weather, which can damage the camera.

- Protect Cables and Connections: All cables and connectors should be weatherproof and insulated. This keeps out ice, moisture, and flammable gases, which could otherwise lead to camera failure or safety risks.

- Allow Space for Airflow: Leave space around the camera so its built-in heater can work effectively. Good airflow helps prevent frost and fog from forming on the housing or lens.

- Position for Sunlight (if outdoors): If the camera is placed outside, try to aim it where it can catch some sunlight. A bit of sun during the day can reduce the risk of ice forming on the front glass.

- Regular Maintenance: Inspect the camera regularly to clean off frost, dirt, or dust. Make sure it’s still working correctly and that no parts are loose or damaged by the cold.

- Follow Safety Rules: Only trained workers should install or inspect the camera in explosive zones. Always follow ATEX safety procedures and wear the right protective gear.

Maintenance and Safety Tips – Maintain Properly!

Regular Checks:

Inspect the camera often, especially during extreme cold. Look for signs of frost, moisture inside the housing, or loose parts that may affect performance.

Clean the Lens Carefully:

Use a soft, dry cloth to clean the lens. Avoid using water or harsh chemicals, as they can freeze or damage the glass.

Monitor System Health:

Use remote access or monitoring software to check camera status. If the image becomes blurry or the feed stops, act quickly to avoid safety risks.

Test Heater and Defogger:

Make sure the camera’s built-in heater or defogging system is working. These features are important for clear visibility in freezing weather.

Follow ATEX Safety Protocols:

Any maintenance done in explosive zones should follow ATEX safety rules. Always use certified tools and wear proper gear.

Schedule Professional Servicing:

Plan for professional inspections at least once or twice a year. Technicians can test seals, heaters, and system integrity for long-term use.

Backup Footage and Logs:

Regularly back up camera footage and system logs. This helps with safety audits, incident reviews, and system performance tracking.

FAQs:

Can ATEX cameras work in freezing conditions?

Yes, ATEX cameras made for subzero environments are built to handle freezing temperatures. Many models can work in conditions as low as -50°C, thanks to built-in heaters and rugged housings.

Where can I use a subzero ATEX-rated camera?

You can use them in hazardous, cold places like oil rigs, gas plants, chemical sites, and mining zones. They’re perfect for areas where both low temperatures and explosion risks exist.

Are all explosion-proof cameras also ATEX certified?

No, not all explosion-proof cameras are ATEX certified. ATEX is a specific European standard. Some cameras may meet other standards like IECEx or UL but not ATEX.

Do ATEX-rated cameras need special maintenance?

Yes, they do. Regular checks are needed to clean the lens, test heaters, and inspect seals. In explosive zones, only trained staff should handle maintenance following ATEX safety rules.

What are the best ATEX-rated cameras for oil and gas fields?

Top models for oil and gas include the ZAEX CZ100, Larson Electronics EXPCMR-IP-POE-4MP, and Spectur F-100. These are tough, certified, and built to handle cold and explosive environments.

Conclusion:

Subzero ATEX-rated industrial cameras are very important for safety and smooth work in cold and dangerous places. These cameras are built to handle freezing temperatures and explosive areas, making them perfect for industries like oil and gas, chemicals, mining, and cold storage.

They let you watch and check equipment from a distance, even in harsh conditions. This helps protect workers, equipment, and also meets safety rules. Choosing the right subzero ATEX-rated camera is a smart move for any business working in risky and cold environments.

Read Also: